The collaboration with the most important exporters of crustaceans from all over the world such as king crab, lobsters and live lobsters, means that our storage facilities have unrivaled product storage capacities, allow us to guarantee hygienic-sanitary conditions at the highest levels at global level. Our technical office has such know-how that allows us to assist the customer in all phases of his work.

For the line dedicated to shellfish finishing and sales plants, the technologies are even more advanced as they must guarantee the purification and elimination of bacteria and viruses as required by the health regulations of the various European countries.

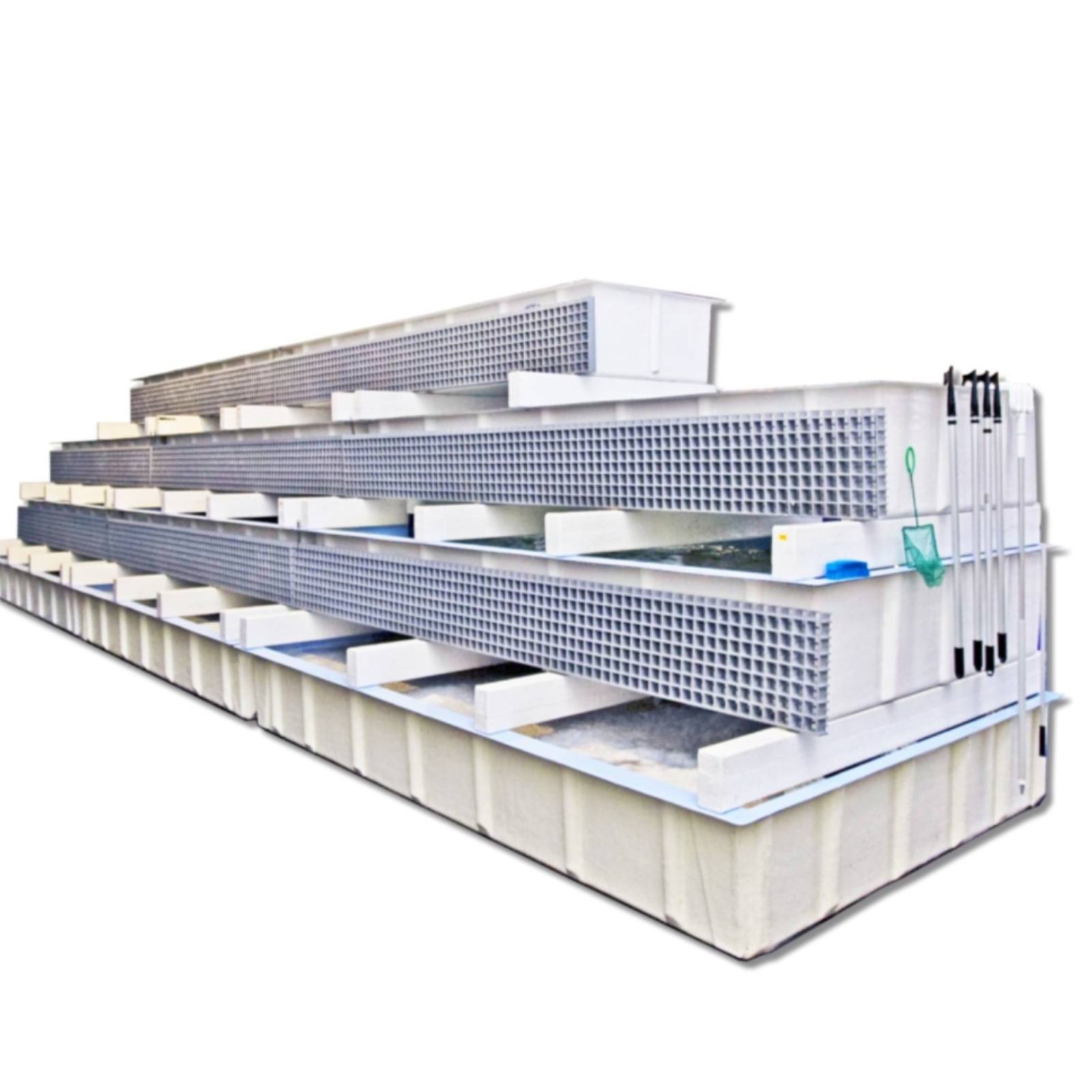

The Ase M Bins model is by now the best plant in the world that can choose a shellfish purification or shipping center (CDM/CSM) to purify, desand and keep alive oysters, mussels, cockles, clams and other species, to break down and eliminate bacterial contamination leaving a product that at the end of the cycle has a live and vital fruit, maintaining its freshness, organoleptic characteristics and food safety. In addition to the possibility of having fast cycles (6-12 hours), the very latest cutting-edge, innovative technologies allow our ASE M BINS to be configured from 3 to 20 bins for each plant.